What happens if SpaceX is successful at achieving its Falcon reusability goals. Here is the video of SpaceX’s plans to recover and reuse the majority of its Falcon launch system.

Let me make some assumptions about a Reusable Falcon (R-Falcon) to make my point that such a system may pose challenges for SpaceX.

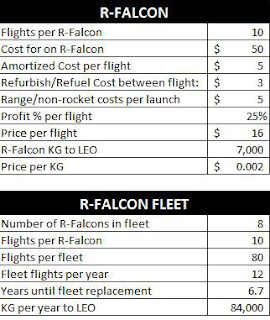

On the surface, an R-Falcon would be great. If my assumptions below are accurate, only $16M per flight, a flight every 30 days, only two thousand dollars per KG. From a consumer perspective this would be great! SpaceX is adding reusability to the large rockets they already have. And they will probably be successful at it. They do seem to achieve what they put their mind to, however, could there be an easier road to reusability? Let’s explore the possibility. First what could a large reusable system like SpaceX’s look like (dollars values in millions)?

I am still amazed we can’t build Saturn V’s today. We built them before. We went to the moon in them for goodness sake! We knew how to build them…why don’t we know now? Two major reasons:

- We don’t have the tooling/plans – long since destroyed or lost

- We don’t have the knowledge – the NASA/contractor engineers have retired/passed away

So here is the problem.

After the initial push to develop the R-Falcon fleet, at the usage rates outlined in the table, you would NOT NEED TO BUILD another R-Falcon for 6.5 years!

So SpaceX could avoid throwing away their tooling (unlike the Saturn V), but could they keep a knowledgeable team around ready to build the next R-Falcon 6.5 years after the first fleet was completed?

And even if you believe eight R-Falcons in the initial fleet is too many and want to reduce the fleet size, demand rates of one per month means SpaceX would only need to make approximately one R-Falcon per year to keep up with demand. Not exactly mass production – 1 vehicle per year. Can you keep the production team “sharp” on 1 vehicle per year?

How can it be, as a consumer, I love the R-Falcon (yay $2k per KG), but as a business, could the R-Falcon be a bad way to prove a reusable launch vehicle? Could the R-Falcon launch too much payload and launch too infrequently?

Let’s talk about an alternate business approach that could address some of these challenges. I said above that my hypothetical R-Falcon has two problems:

- Launching too much payload

- Launching too infrequently

How could a new hypothetical company do reusable launch better? What if you launch less mass but launch more often? So let’s make up a hypothetical launch system – the “Kinglet.” Since this is a business blog, let’s not get bogged down into the technical details except that instead of launching 7,000KG per flight, the Kinglet will launch 100KG. And instead of paying the R-Falcon’s $5M for range access per flight, the Kinglet pays $200K per flight for its range or range-like services (airport, spaceport, other?). Here is the table for such a system (dollars values in millions).

How could a new hypothetical company do reusable launch better? What if you launch less mass but launch more often? So let’s make up a hypothetical launch system – the “Kinglet.” Since this is a business blog, let’s not get bogged down into the technical details except that instead of launching 7,000KG per flight, the Kinglet will launch 100KG. And instead of paying the R-Falcon’s $5M for range access per flight, the Kinglet pays $200K per flight for its range or range-like services (airport, spaceport, other?). Here is the table for such a system (dollars values in millions).

The Kinglet is a smaller launch system but aims for a higher flight rate, targeting weekly flights instead the R-Falcon’s monthly flight rate. As a potential customer, I do not like the 10x higher price I pay to use Kinglet ($20K per KG vice the Falcon’s $2K). But flying weekly may be attractive to some customers. Overall though, this appears to be bad for customers (most customers could wait a month to fly). But from a business perspective, all things being equal, a small reusable launch system like Kinglet has a much higher probability of success because it starts small.

Where the Falcon struggled to keep its production line open with only one new vehicle per year, the Kinglet will need to produce five systems per year to keep up with demand. Now five launch vehicles per year is still not mass production, but those volumes will, not only keep the production team sharp, but provide five times the opportunities to roll in product and production improvements into the newer vehicles than would be possible on the R-Falcon production line.

Could a smaller reusable system avoid R-Falcon's hidden pitfalls? Maybe.

Could a smaller reusable system avoid R-Falcon's hidden pitfalls? Maybe.

So the last question to ask is, what needs to be launched at least weekly with a mass of under 100KG?

Here is the excel file with tables from this post if you want to change the assumptions.

You introduce two types of RLVs but constrain both to an ELV world that is unchanged from what we now have. In particular, you assume no change in demand even after several years have passed with significantly lower launch costs available. I think that level of pessimism about demand is unwarranted. Lower costs as well as quicker access to space will attract new demand very quickly.

ReplyDeleteThe ways the satellite industry would change with low cost launch is too big a subject to go into here but it would definitely change dramatically and lead to many more sats going to space.

Launch cost is one of the primary limiting factors to NASA's space science program. Lots more projects would appear with lower cost access to space.

Putting Bigelow habitats into orbit and traveling to and from them become much more affordable. Bigelow has spoken of the need for weekly flights.

Etc, etc.

In his press conference in which he introduced the rF9 plan, Elon outlined goals of full reusability, rapid turnaround, 1000 or more flights per vehicle, and price per kg in the low $100s. It's obviously highly likely the first rF9 will fall far short of those goals and have perhaps only the limited capabilities you describe. However, I think rather than building a fleet of such highly limited vehicles, they will instead improve the design over several iterations till they are far more capable and can lower costs substantially below $2000/kg . (The FH is already supposed to achieve that cost for its large payload.)

Meanwhile, Blue Origin will be developing its competing RLV and perhaps do as well or better than the rF9. The suborbital RLV guys also have plans for orbital RLVs as well.

You assume that no one else will want to buy and operate their own RLVs. It's quite likely that NASA, DoD, other countries, and private companies would want to own their own fleets of RLVs. (The book "The Rocket Company" by Stiennon and Hoerr emphasizes the benefits of separating RLV builders and operators.)

A world with fully and rapidly reusable vehicles will be quite different than our current ELV world.

- Clark

p.s. The Saturn V blueprints are actually still available. If it was really important to do so, one could be built today.

Clark:

ReplyDeleteto sum up your arguments - (1) with demand, the business case for RLVs could close and (2) the capabilities of R-Falcon will be far superior to the capabilities I outline in my tables above.

Sadly, I worry that increased capability only makes the "production line" problem worse, not better. If one R-Falcon can fly 1000's of times per vehicle with short turn-arounds (promised but I have my doubts), one vehicle could service the whole industry in the early days. one vehicle. only one. yikes! I am arguing for perhaps a way to keep the production lines open by targeting smaller/cheaper vehicles like a 100KG Kinglet.

But I completly agree that selling these vehicles to "spacelines" you may be able to increase that production number. This approach does not fully bypass the demand question, but it does allow multiple operators to chase the same customers.

Great comments. I am hopeful like you!

The killer is in the number, 12, for flights per year. As you note, higher launch rate results in faster cycling of fleet vehicles. The once a week rate has been claimed to be the threshold at which reusable launch vehicles become viable, and it certainly would help in this case.

ReplyDeleteI think that SpaceX is counting on a fairly radical increase in demand. The thing is, they might not get that demand without either creating it themselves (with a little vertical integration perhaps) or by knocking out some one-time development risks with some strategic R&D.

Hi Colin,

ReplyDeleteThe issue of a high flight rate requirement for RLVs has been around for a long time and I agree that it is not a crazy concern. My argument is that you are taking it to an unwarranted extreme by assuming no positive market response at all.

"in the early days"

That really gets to my main point. Firstly There is no instant transition between one day having all ELVs and the next day a having a rF9 that's quickly clearing out all the payloads in the space transport queue. Secondly, new launch demand can arise very quickly within the "early days".

The initial rF9 (or Blue's RLV or whatever) will have a start up period of some number of years. Some payloads will not be compatible. (E.g. big sats going to GEO. either need an expendable upper stage or development of a reusable tug.) Its flight rate will no doubt start out quite low. Probably have to wait for rF9 ver.2.0 or 3.0 before it really becomes a robust, reliable high rate transport. (Remember also that the rF9 involves three major reusable parts, each of which will have its own development life. E.g. maybe at a given time the first stage can be flown 100 times and the second stage only 10.)

In the meantime, many of its payloads, such as Bigelow habitats, by their nature will add new payloads/passengers to the queue. Another example of this is the ISS. Utilization will quickly rise since within the same transport budget, NASA can send far more astronauts and researchers (and cargo to supply them). This will encourage development of new uses of the ISS, which in turn will add more transport demand.

Also during this meantime, lots of LEO satellite services concepts that are marginal at best at current launch costs will become financially feasible at the lower costs. Many of these involve constellations of many satellites.

The lower cost, quicker access to space means the development of such satellites can be faster since they don't need to be as hyper-robust and long-lived as they need to be now due to expensive, infrequent access to space. So the queue can grow quite quickly.

The recent Smallsat meeting in Utah had about 1200 people attending, a good many of whom are involved with a satellite project that needs a cheap ride to orbit.

So the bottom line is that there is a lot of latent demand ready to respond quickly to a big drop in launch costs. A transition to RLVs may not be smooth but the sooner it gets underway the better for space development.

If you want to develop space, even at RLV costs something has to stay in space. It certainly won't be complex science or highly engineered payloads at today's payload development costs. Clear thinkers have for years posited that it will be the launch vehicle (or a portion of it) themselves, certainly the upper stages, if the cost of space development is to decline with the cost of transport. Thus your conundrum is easily solved.

ReplyDeleteThis is assuming you (or the RLV developers) want to develop space. At least one of them indicates he does. It doesn't appear that NASA or our government actually wants to develop space since their proposed launch vehicle does not incorporate the now easily implemented reusability features. Thus launcher size is irrelevant if one posits the principles actually want to proceed with any credible large scale space development goals.

"We don’t have the tooling/plans – long since destroyed or lost

ReplyDeleteWe don’t have the knowledge – the NASA/contractor engineers have retired/passed away"

Nonsense! We have had the ability to build a Saturn V class vehicle derived from the Shuttle since the first SDHLV study was done in the late 70's. We don't need an actual rivet for rivet replacement to fulfil the role of a Saturn V, just a vehicle of similar capability. The Shuttle was always payload plus a 70 ton spaceplane that had to be placed into orbit but only marginally contributed to the payload.

What we lack is a non-government payload and a non-government market that yet requires a vehicle of that size. The reasons for it's non-existance are purely economic and not technical.

Clark:

ReplyDeleteI am hopeful like you that the demand will be there. Imagine the possibilities if SpaceX is really able to hit the price points that are being discussed. Hundreds of dollars per KG to orbit! May I be the first to say Yahoooooo to that. And I like your outline for how the demand probably will grow for an RLV service at low costs (and I have a few other ideas that should grow demand as well that I will save for a future post or a future business plan).

I guess this is a “hedge-your-bets” blog post. SpaceX is in a tough (if enviable) spot. They already have a Falcon family of launchers. So it makes sense they try to increase reusability within this family of vehicles (that is what I would do). But if demand grows for their reusable vehicle slower than projected, I worry about closing the business case for the R-Falcon (the production line argument outlined in the blog post above being an element of that argument). Even if you are correct and I am overly concerned about production levels, the real question (I think we can both agree on) is the unknown demand level. And this is my main concern why I am advocate for SpaceX competition to come not from the Blue Origins alone but from the NanoSat launcher class, what I have been referring to as Kinglet-class.

A Kinglet-class vehicle (100KG to LEO with high flight rates and low integration cycles) wins at any demand level.

If demand is lower initially, the Kinglet requires less demand to maintain a full manifest thus has a good shot at still closing its business case.

If demand is higher as many are predicting, then there is probably room for several players within the RLV to LEO market.

Developing a Kinglet-class vehicle may offer a less risky approach to reusability…even if SpaceX may not be able to easily take that path themselves.

~Colin

I also wanted to highlight Clark's last statement which is worth repeating...

ReplyDelete"A transition to RLVs may not be smooth but the sooner it gets underway the better for space development."

Agreed!

>> A Kinglet-class vehicle (100KG to LEO with high flight rates and low integration cycles) wins at any demand level.

ReplyDeleteYou are assuming several things with the Kinglet:

1) The market in smallsats is qualitatively similar to that for largesats. This just is not the case. The only reason these get to space at all is because they piggyback for pennies on the dollar. I think in the long run this is good for the Kinglet class, mainly because the customers will be a lot more elastic to price. But that's only because the price that smallsats will pay is already far lower than what largesats will pay, so it make the business case harder to close to recoup R&D.

2) It's technically a lot harder and more expensive to launch 100kg 50 times than it is to launch 5000kg once. Some Soviet ICBMs did small payloads for relatively low prices in the '90s when they were firesaling them, but their reliability sucked and that was a market glut not driven strongly by price signals. Pegasus is the only thing we have that's close now, and it's about 3-10X more expensive per kg than medium and heavy lifters (and it hasn't flown in years). The path to r-Kinglet is a lot further than that to r-F9 or r-Blue.

3) You seem to be assuming that a reusable system would spring fully formed 8 at a time from the factory, which would then shut down. Nascent buyers will go out of business or mothball their vehicles, which may not be good but will absorb some startup cost from the manufacturer. Lessons will be learned and the line will stop to update with them, older tail numbers will be pulled back in for overhaul, etc. As Clark mentioned, parts of the system may remain expendable for some time, giving the factory something to build. It will take many years from test flights which signal to potential vehicle and payload customers that this is imminent, to actual regular reusable service. I agree the crux is the demand elasticity, but I don't buy that the factory will choke itself off with initial high production rate. If anything, the opposite will be true.

All in all, your post seems to boil down to, "If there is no elasticity of demand these guys are screwed." To which I would say, "duh." Barring unforeseen or pessimistically understood markets, up until somewhere in the $100s/kg, you're eating your own revenue to corner a shrinking market. And I think it's a real possibility, maybe >50%, that the companies will not get launch prices low enough fast enough to the point where mass markets finally bend the elasticity to >1. But I think the production quandary you cite will prove to be a problem the companies wish they had when the time comes.

"1. We don’t have the tooling/plans – long since destroyed or lost

ReplyDelete2. We don’t have the knowledge – the NASA/contractor engineers have retired/passed away"

Really? Those are the only two reasons you can think of? How about "NASA can't build a rocket within budget to save its life for political reasons"? Just look at SLS. It's a politically driven cost and economics issue, not technical.

You're also confusing "cost" and "price".

Quick: Who's the most profitable oil producer in the world? Saudi Arabia, that's who. They have the lowest product costs and they charge the same price as Canadian oil sands.

An RLV lowers SpaceX's costs, not its prices. It's already the low-price provider and is wrapping up the entire market with its ELVs. If they cut their prices another 30% they could put Boeing and EADS out of business (but for political lobbying). Then they could sit back and collect fat checks all day long while Blue Origin or whoever continues to struggle to even reach 100 km, let alone orbit.

And that's before they even start to increase demand for space access with new business models. How about private telescopes on the dark side of the Moon? How about Bigelow stations and regular traffic to and from there with astronauts from Japan and Singapore? And then there's Planetary Resources.

--

Let's remember that Henry Ford lowered the price of car production 10x. How'd that work out for him? Was he able to keep his manufacturing employees sharp and practiced?

Space X did well and I think it will do well.

ReplyDelete